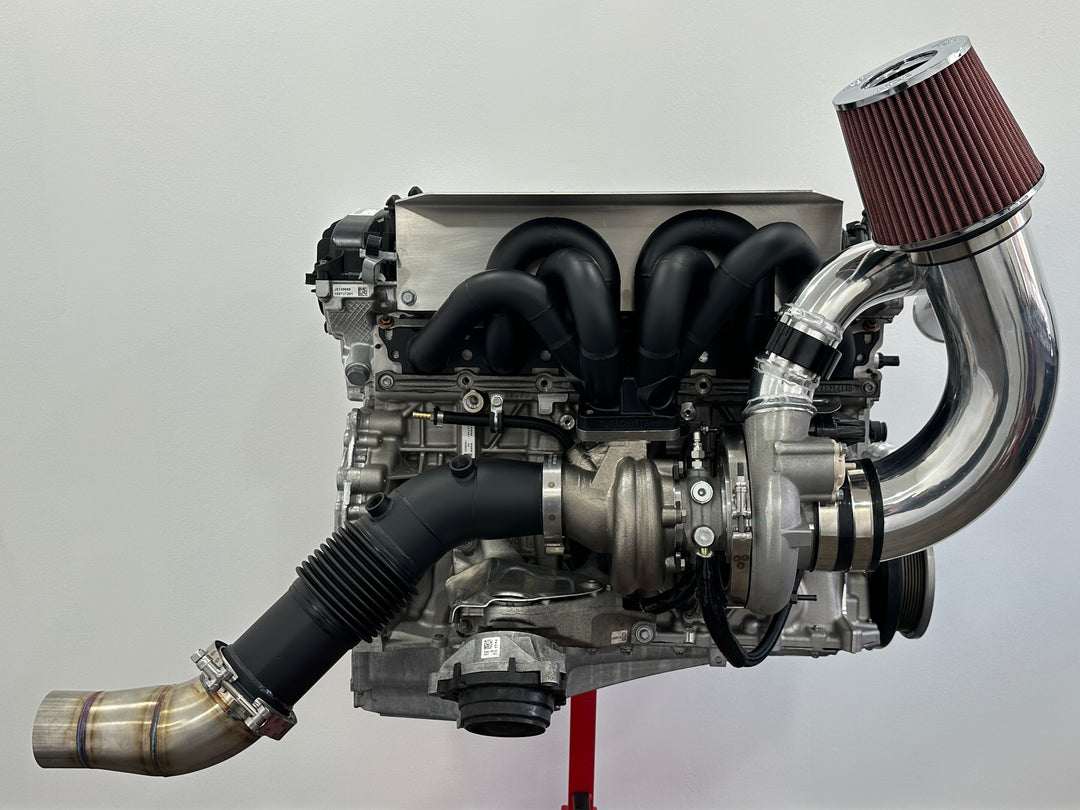

Introducing the N55r26: The Ultimate High RPM Track Engine

For high RPM enthusiasts looking for a thrilling driving experience, the N55r26 is a game-changer. Designed specifically for track use but versatile enough for daily driving, this engine boasts a 9,000rpm rated rev limit, offering an exhilarating blend of performance and reliability. The N55r26 package includes a custom one-piece de-stroked billet crankshaft, custom rods and pistons, upgraded valves, springs, and retainers, head porting, engine assembly, a billet oil pump, comprehensive machine work, and vital oiling system upgrades. With a build time of 12-14 weeks due to the intricate machining of the 4340 billet crankshafts, this engine is a true testament to engineering precision. For those using the N55r26 for road racing, it is recommended to use the S55 oil pan and vacuum oil pump system. This setup prevents oil starvation during high-speed left-hand corners, ensuring optimal performance under demanding conditions.

The N55r26 is available in three stages, each featuring the same foundational design elements like head porting, lightweight valvetrain, and custom components. Stage 1, priced at $19,500, offers 650-700whp with a standard open deck block, ARP 2000 head studs, and head port cleanup. Stage 2, costing $22,500, delivers 850-900whp with a closed deck block conversion by CSS, ARP 2000 head studs, and head port cleanup. Stage 3, at $23,999, pushes over 1000whp with a closed deck conversion. F CSS, ARP 625 head studs, Schrick exhaust camshaft upgrade, and a 5-axis CNC ported head. The stock open deck block is limited to around 700whp due to the potential for sleeve cracking above this power level, making the higher stages ideal for those seeking extreme performance.

The standard N55B30 engine, with an 84mm bore and 89mm stroke, is designed for low RPM efficiency, producing substantial torque between 2,500-4,500 RPM. However, the N55r26 offers a reimagined design with an 84mm bore and 79mm stroke, creating an over-square configuration that favors higher RPM power. This design results in less low-end torque but significantly more high-end horsepower. The increased piston dwell time, reduced frictional losses, and enhanced component longevity ensure that the N55r26 not only performs exceptionally well but also lasts longer under high-stress conditions.

The de-stroked N55r26 provides several performance enhancements, including faster throttle response, reduced rotating mass and mean piston speed, and improved durability at 9,000rpm. Its design allows for better gear-down capabilities with differential ratios of 3.91 or 4.10, making it ideal for track enthusiasts who demand the best from their engines. To ensure a rebuildable core, the engine must be a complete factory engine from oil pan to valve cover, in good used condition with no cracks, holes, or signs of oil starvation. The N55r26 represents the pinnacle of high RPM track engines, offering unmatched performance for those seeking an exciting driving experience. Whether for track use or spirited daily driving, the N55r26 delivers power, reliability, and longevity.